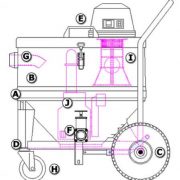

| Voltage | 120 V | Motor Power | 1400 W |

| Number of Motors | 1 | Vacuum (inH2O/inHg) | 107/7.9 |

| CFM | 112 CFM | Length | 33 in |

| Width | 28 in | Height | 37 in |

| Capacity | 7 gal | Bottom Discharge Size (Solids) | 8 in |

| Liquid Discharge Size | 1.5 in | Vacuum Inlets | 2 in |

| Casters | Heavy Duty Non-marking | Pump Discharge Rate | 38 gal/min |

| Option | 38 gallon/minute discharge pumpAccessories & Hoses for all applicationsSilo conversion: For stationary applications | Note | 220 single phase available |

RUWAC WET VACUUMS

Free!

Only Ruwac, known for their filtration of dry material, could use their ingenuity to develop the best industrial wet vacuum. Same Fiberglass Reinforced Compression Cast Composite so you never have to worry about the housing denting or rusting. The WSP2000 has a liquid capacity of 7 gallons. An optional return pump allows the operator to vacuum and pump liquids simultaneously

With so many features in an industrial vacuum, isn’t it time you tried Ruwac?

- Specifications

- Superior Innovation

- Recent Applications

- Specification

- Videos

- Compact size, yet powerful & Quiet!

- Modular construction, Upgradeable

- Composite housing, rugged & durable

- Vacuum shut-off float

- 8″ bottom discharge for solids

- 1.5″ liquid discharge

- Auto shut off when a predetermined liquid level is reached

- Front two swivel; rear are rigid

- Foot lever activated discharge

- Extensive parts commonality; All parts in stock

- Removal of liquids from pressure washers

- Vacuum and pumping water from rooftops

- Vacuuming and pumping liquids from a parts washer

- Modular Oval Construction, designed for flexibility, upgradeableOur modular oval construction offers the maximum design flexibility. Changes to the vacuum can easily be made in the field. i.e. change motor decks.Oval vs RoundOur industrial vacuums were brilliantly engineered using the “Oval Principle”. Many other industrial vacuums are constructed using a standard round collection container, adding a filter and a motor. Ruwac’s are constructed with an oval shaped housing,

- Fiberglass Reinforced Compression Cast Composite, will not Rust!Ruwac manufactures all of our machines out of a compression cast composite. This material is put into a press at 900 tons of pressure, insuring a precise mold every time. The material will not rust, is dent free, and abrasion resistant. We warranty all compression cast components for life, guarantying you a long lasting vacuum.

- 8″ Bottom discharge for solidsSludge and collected solids can be discharged by using the foot lever actuated dump valve

- Tip resistant counter-balanced base.

- Powerful By-pass vacuum producerRuwac’s wet industrial vacuum cleaners use only the highest quality dual stage by-pass motors available. These individually cooled motors bring in outside fresh air to cool the motors. Cheaper flow through type motors use the vacuumed air to cool the motors, and if they do not filter well, all that dust goes through the motor too.

- 2.0″ bottom liquid discharge

- 2″ Vacuum inlet

- Heavy duty non-marking casters: rear with pneumatic tiresRuwac vacuums have large heavy duty non-marking swivel casters on the front and large heavy duty pneumatic tires on the rear. Large rear tires allow the wet vacuum to handle many different terrains. They are very durable and stay on!

- Positive closer floatThe Wet vacuums have a float shut off to prevent overflowing.

- Optional 38 gallon/minute return pump available for both models.