| Voltage | 120 V | Phase | Single |

| Amps | 16 A | Horsepower | 1.5 hp |

| CFM | 150 CFM | Vacuum Pressure | 5.5″ Hg |

| Filter Area | 13 sq. ft. | Capacity | 9 gal |

| Inlet | 2″ w/bronze cast deflector | Filter Efficiency | 99.9% @ 0.5 microns |

| Casters | 3″ Heavy Duty conductive | Includes | 151510DEX-SP, Dust Ex Accessory package |

| Certification | Class I, Division 1 and 2, Group D; and Class II, Division 1 and 2, Group F & G |

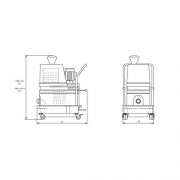

W151EX EXPLOSION PROOF VACUUM

Free!

W151EX

Safely Remove Combustible Dust

Without the Risk of an Explosion!

OSHA Compliant

- MicroClean filtration prevents filter clogs and costly replacements

- Carbon-impregnated compression cast composite housing for lifetime durability

- ETL Certified to UL Standards for Combustible Dust Collection (Class I, Group D and Class II, Group F & G)

- NRTL Certified Explosion Proof Vacuums

Don’t Let A Combustible Dust Hazards Happen To You!

You need the FRV Series by Ruwac The Safest Vacuum on the Market!

- Required for safely collecting combustible dust

- OSHA compliant, certified explosion proof vacuum rated for continuous duty and is completely serviceable nationwide

- The W151EX meets the NFPA 654 requirement that the storage container is less than 8 cubic feet.

- Compression cast composite housing will not dent, break or rust

- Carbon impregnated housing is chemically neutral and static dissipating (<10-6 Ohms) to eliminate static discharge

- Modular housing backed by our lifetime warranty

- Industry-leading MicroClean filter is 99.9% efficient at 0.5 microns, preventing filter clogs and cutting down on costly filter replacements

- Foot-actuated 9 gallon dustpan allows for easy, dust-free emptying

The build up of combustible dust can pose a very real and immediate threat of an explosion inside your manufacturing or storage facilities. To prevent such a catastrophe from happening, you need Ruwac’s EX Series portable explosion-proof vacuums. Manufactured under strict quality control here in the United States, our certified industrial vacuums are intrinsically safe with all parts fully grounded, static dissipating and guaranteed to be spark-free by an impact.

- Specifications

- Specification

- Applications

- Associated Products

- Conductive Metals

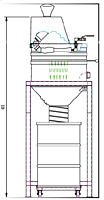

- Modular Oval Construction, designed for flexibility, upgradeable

Our modular oval construction offers the maximum design flexibility. Changes to the vacuum can easily be made in the field.

i.e.: change motor decks, add HEPA filtration

- Oval vs Round

Our industrial vacuums were brilliantly engineered using the Oval Principle. Many other industrial vacuums are constructed using a standard round collection container, adding a filter and a motor. Ruwac’s are constructed with an oval shaped housing. This shape has proven to be the most effective when dealing with fine dust.

- Fiberglass Reinforced Compression Cast Composite, fully grounded

Ruwac manufactures all of our machines out of a compression cast composite. This material is put into a press at 900 tons of pressure, ensuring a precise mold every time. The material will not rust, is dent free, and abrasion resistant. We warranty all compression cast components for life, guarantying you a long lasting vacuum. Every vacuum is fully grounded for safety. The composite material on the DS1000 is impregnated with carbon.

- Long Life Oversized Dustless filter system, 99.9% @ .5 microns

Every Ruwac Industrial Vacuum is designed for returning only clean air to the work environment. Our oversized standard filter is 99.9% efficient at .5 microns. This unique designed filter allows the operator to pick up fine material in large quantities, maintaining a low filter loading. Our average filter life is 5 to 7 years, (assuming proper maintenance) and carries a warranty of 3 years. Some applications require even more filtration than our standard .5 microns. For these customers, HEPA, ULPA & Active Charcoal Filters are an available option on all our equipment. With our standard filtration down to .5 microns, you might never change your HEPA Filter! HEPA, ULPA & Active Charcoal Filters available. A truly dustless vacuum.

- Lever Actuated Drop-down Dust Pan for easy emptying

What first impresses everyone about the Ruwac vacuum is the easy to empty drop down dustpan. Just lift the lever with your foot, and the dustpan is lowered to the floor. Push the vacuum forward, and the dustpan is easy to reach and empty. To replace the pan, no alignment needed, just push it under the vacuum and step down on the lever.

- Tip resistant counter-balanced base, with low level hose inlet

Are you frustrated by your vacuum turning over all the time, either the vacuum weighs little, or it is a top heavy drum top model. With Ruwac’s low inlet and counterbalanced base, the operator can pull the vacuum via the hose without ever tipping the machine over.

- Continuous Duty Motor for long motor life

The DS1000-EX uses American made continuous duty explosion proof motors.

- Inclusive sound suppression for quiet operation

All of Ruwac’s industrial vacuums offer inclusive sound suppression. For the Ds1000-EX the sound level will be about 75 dBA.

- Manual external filter shaker control for easy filter maintenance

With Ruwac’s oversized grounded filters, maintenance is reduced to almost nothing. Each time you empty the dustpan, give the external shaker bar one or two shakes and you are ready to return to dust-free cleaning.

- Heavy duty non-marking conductive casters: rear with locking brakes are standard.

3″ heavy duty non-marking conductive swivel casters on the front and large heavy duty non-marking rigid casters, with brakes on the rear. They are very durable and stay on! 6″ casters available with upgrade. They are very durable and stay on!

- Cast bronze deflector to knock material out of the air stream

Our cast bronze deflector knocks material out of the air stream so that none of the material you vacuum hits the filter directly. Material hits the deflector and then spins around our oval designed dust pan. This slows the material down even more, so only the finest material ever contacts the filter. This allows you to have much longer vacuum cycles and be more productive because time is not spent cleaning or replacing filters!

- Light Housekeeping

- Point of source collection

- Class 2 Div 2 & ATEX Zone 22 approved machines available W151, please contact us with your application details

- W151EX is approved for Class I Div 1, 2 Group D and Class II Div 1, 2 Group F & G

- Need additional filtration and collection capacity? Check out Ruwac’s P2151-EX, featuring a motor rated for continuous duty, a 24-gallon collection capacity and 48 sq. ft. of MicroClean filtration!

|

|

|

|

| WB151 Bagger Vac | SV-D11 Silo | R201 | W151 |

|

|

|

|

| Pre-Separators for extra collection capacity | HEPA Filter | Overhead Cleaning Package |

Due to the instability of conductive metal dust contained in a confined space along with the fact that the slightest outside ignition source could ignite the already contained dust; Ruwac strongly recommends the use of an immersion separation system for all conductive metals. Sometimes the material is explosive but not the atmosphere. It is not safe for some of these materials to be vacuumed into a dry vacuum.

For these materials, we recommend a Ruwac Immersion Separation System for safe containment.

With an NA-250 or an NA-35, 100% of the intake air is completely submerged in liquid, the chance of an outside ignition source entering the vacuum is safely ruled out.

These materials may include, but are not limited to; aluminum, magnesium, titanium, zirconium, sodium azide, hydrogen, lithium, potassium, rubidium, cesium, francium, & glowing embers, etc?

If the atmosphere is classified as explosive, let us know and we can quote you the correct approved equipment.

Should you decide that an immersion separation system is not required for your application; our FRV110 or the FRV100 are the only alternatives that can be considered.

NFPA Code 484 Chapter 12.4.3.1 Vacuum cleaning systems shall be used only for removal of dust accumulations too small, too dispersed, or too inaccessible to be thoroughly removed by hand brushing. ie sweep & shovel large piles, vacuum only light dusting.

Our FRV110 vacuum is certified to UL 1203 Class II Group F and G. The unit is constructed with certified Group E motor and switch gear for use in Group E areas. Please make note that the definition of a certified explosion-proof vacuum is that the vacuum cannot give off an ignition source, the vacuum has 2 sources of ground, the vacuum has components rated for the atmosphere it will be operating in, the vacuum is non-sparking by impact, all of the hoses and tools have a resistance less than 1 megohm, all materials of construction are nonmetallic and the vacuum cannot build up a static charge during use or transport. Even though the vacuum is defined as explosion proof with all of these safeguards the fact remains that it can still catch fire or blow up. All unstable materials especially conductive metals require the use of an immersion separation system to safely rule out all risks of fire and or explosions. No dry vacuum, not even a Ruwac dry explosion proof vacuum can guarantee that when vacuuming conductive metals.